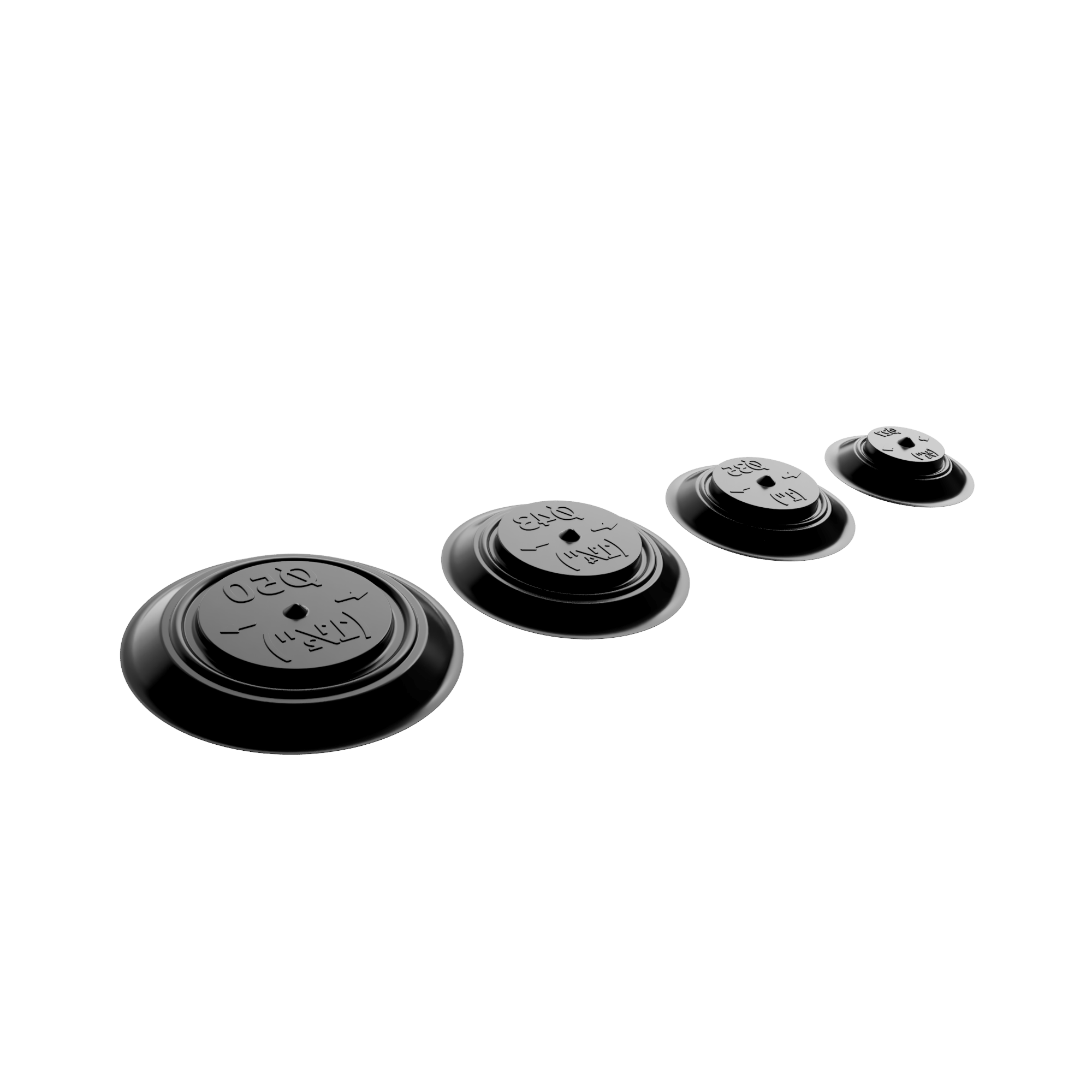

TruDesign Mould Plugs

£1.15 – £1.54 Inc VAT

TruDesign Mould Plugs are designed to form the recess in a fibreglass (GRP) hull that is required for the flush fitment of a given size TruDesign Recessed Skin Fitting.

Documentation

TruDesign Mould Plugs

Moulded from Polypropylene, they are single-use, throwaway items that significantly reduce the time and complexity traditionally involved with the installation of Recessed Skin Fittings. Now, each recess can be formed in the hull during fibreglass lay-up, rather than requiring the hull to be CNC machined or manually cut and shaped at each thru-hull position after demoulding.

Features

- Makes a Pre-form recess in the layup stage of GRP hulls that fits exactly a TruDesign approved Recessed Skin Fitting – Saves complex machining of bevelled edges in the GRP hull.

- Bevelled Edges are now part of the Gelcoat – The integrity of the hull is maintained, minimising wicking down end grain & delamination.

- Injection moulded Polypropylene material – ‘Waxy’ feel to material gives non-stick properties for easy-removal from the hull.

- Reversed text size info embossed on part – After removal from the hull the size of the hole saw required and size of the Recessed Skin Fitting to use is left imprinted on the fibreglass (reading the correct way).

- Centre drill locator – Forms an indentation in the centre of the recess perfect for positioning the centre drill of a hole saw in to before cutting.

- Gluing ‘channel’ – Forms a channel directly under the flat face of a Recessed Skin Fitting head for increased contact with the adhesive or sealant.

3D Interactive Model

| Weight | N/A |

|---|---|

| Size | 3/4", 1", 1 1/4", 1 1/2" |

Related products

Adapters

£6.50 – £8.89 Inc VAT

TruDesign Reducers, Connectors and Clips

£0.72 – £1.16 Inc VAT

TruDesign Sanitation Equipment

£3.70 – £12.20 Inc VAT

TruDesign Hosetails

£6.34 – £9.26 Inc VAT